Stable Forest Machines

Stability and safety whatever the job

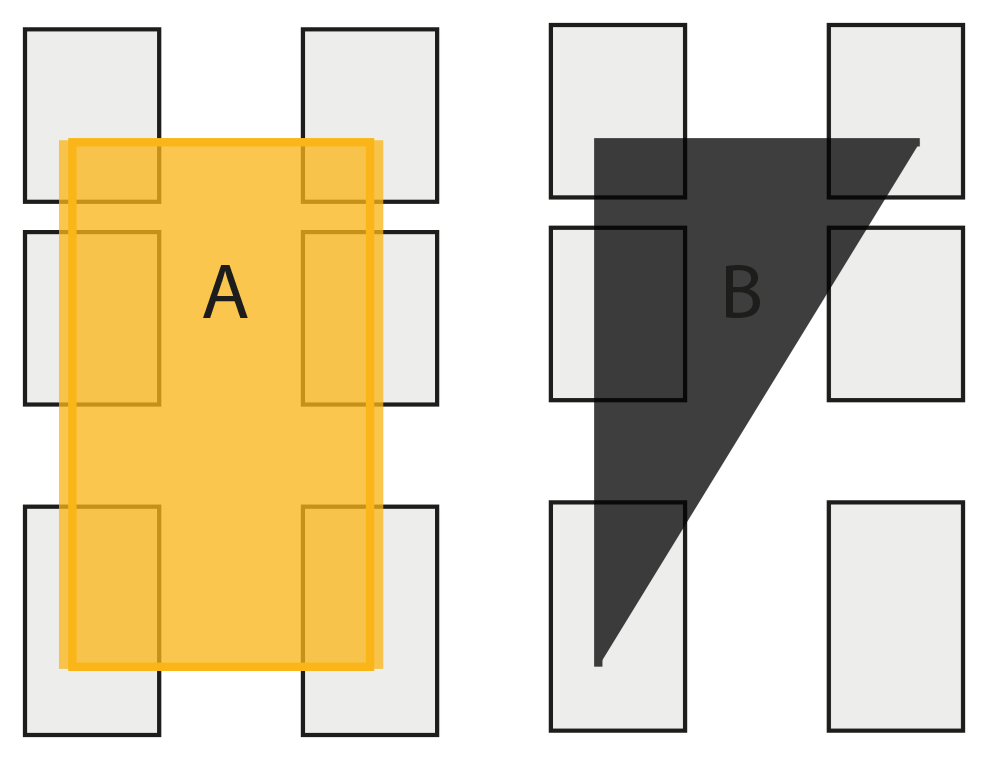

The unique pendulum arm technology means that the harvesters in Eco Log’s 500 series can always work with great stability regardless of the conditions or incline of the terrain. Since each wheel can be raised and lowered individually and thereby adapted to any irregularities or obstacles, the harvester can maintain maximum stability, with each of its four corners resting firmly and safely on the ground (Figure A – Harvester with pendulum arms, Figure B – Harvester without pendulum arms).

Even on very steep inclines, the harvesters can work with unbeatable levels of stability. The entire machine can be leveled into a horizontal position and the working position can be adjusted with the pendulum arms to ensure that the center of gravity remains centered within the machine. The optimal working position allows the operator to work safely and with peace of mind without the risk of the machine tipping over even in sloping and uneven terrain. By lowering or tilting the machine, the center of gravity can be kept low and optimally positioned, ensuring extremely favorable baseline stability in all our

pendulum arm harvesters.

- When harvesters in the 500 series are being driven, the pendulum arms are set to the float position, which means that the ground pressure remains evenly distributed between the four corners of the machine at all times, ensuring maximum stability regardless of the ground below.

- When operating the crane, the pendulum arms are locked in the optimal position for equal ground pressure at all four corners, so that the machine remains firmly planted on the ground.

- Eco Log’s eight-wheeled harvester has an extremely low center of gravity and, consequently, great stability regardless of the underlying terrain and when operating the crane.

- The powerful crane makes both the head and the timber easily lifted and controlled, resulting in a more stable work cycle.