Forwarder 584F

The Eco Log 584F belongs to the new range of F-forwarders developed for high comfort and easy servicing for an effecient forestry.

In Eco Logs F-series all the best qualities from earlier generations has been preserved, developed and strengthened through even higher serviceability, driver comfort and new design with an updated color scheme.

The machines are equipped with stage V engines from Volvo Penta, which are characterized by high reliability, efficient performance, quick response and environment friendliness.

TRACTIVE FORCE

LOAD AREA

*Depending on load carrier

ENGINE POWER

LOADING CAPACITY

- The driveline of the machine has a powerful bogie customized for the high traction and load capacity that distinguishes Eco Log 584F from other forwarders of the same size.

- A standard pump displacement of 175 cubic centimeters (cc) or optional 210-cc pump (10,7 cubic inches or optional 12,8 cu. in.) enables the unit to be used with a wide choice of cranes. High oil flow makes it possible to perform simultaneous movements, increasing capacity as well as flexibility.

- The forwarder cab has been designed and equipped for high operator comfort and spaciousness. The excellent visibility gives the operator a clear view of the work area

- The grill swings open for easy access and cleaning.

- The large-dimensioned fenders house easy-to-access batteries, as well as the tool box.

- The urea tank has been placed together with the central lubrication unit, fuel and hydraulic tank to facilitate easy access and re-filling.

- The machines are equipped with new radiators optimized for Stage V.

Tech information

Loading capacity, kg

Weight, kg (lbs)

Width (A), mm

Height (B), mm

Length (C), mm

Ground clearance (D), mm

Length loading bay(E), mm(in)

Approach angle, °

16 000

21 000

2 910**

3840

10625 (11225)****

650

5010(5610)****

40

Type

Fulfils emission requirements of

Power, kW(hp)

Torque, Nm

Fuel tank, l

6 cyl. D8 – 7.7 l

Steg V/Tier 4F/stage III*

210 (286)

1237

195

Type

Approximate tractive effort, kN

Speed, km/h low gear

Speed, km/h high gear

Hydrostatic mechanical

225

8,5

20

Pump, cc

Pressure, bar

Hydraulic tank, l

175 (opt. 210)

235

180

Standard

Option

710/45-26.5’’

800/40-26.5’’

Lifting force, kNm(lb-ft)/ reach alternatives, m(ft) (Cranab, FC13)

Lifting force, kNm(lb-ft)/ reach alternatives, m(ft)(Epsilon S110F)

Lifting force, kNm(lb-ft)/ reach alternatives, m(ft)(Cranab FC16)

Lifting force, kNm(lb-ft)/ reach alternatives, m(ft)(Epsilon X120F105)

Lifting force, kNm(lb-ft)/ reach alternatives, m(ft)(Epsilon X140F105)

——-

——-

165/ 8.5, 10

159/10.5

——-

*Only in market areas outside the EU, USA & Canada

**With standard wheels

***Dependent on length of rear frame

****Maximum length with frame extension

In collaboration with Epsilon, we at Eco Log have developed ETC – Eco Log Tip Control. Our system for crane tip control is a driver support function that allows you to optimize your crane operations, increase productivity and enjoy a more relaxed workday where you feel alert and rested during as well as after you shift.

ETC is an intelligent system which means that it is self learing and therefore adapts and develops itself as you use it.Thanks to the function of the sensor´s, you gain a smoother and more precise crane movement and position. The placement of the sensor´s in the crane generates a robust and reliable system where maintainance is conducted in a smooth and easy way.

With a simple push of a button, you switch from the tip control function to operating the crane manually. This means that you can always customize the work based on your different needs and at the same time ensure a high techincal utilization on your machine since you can carry on working manually when it is time for service and maintainance of the crane tip control system.

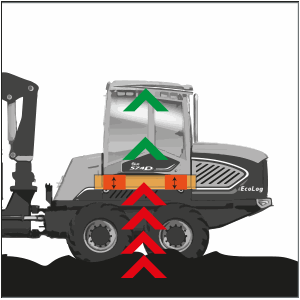

With Eco Log CushionDrive™ the operator will enjoy a significantly improved working environment.

Eco Log Cushion Drive is a damping system and feature option for our three forwarders in the larger segment. Cushion Drive enhances the operator comfort by reducing bouncing, sound and rolling, making the cabin a comfortable work environment for long days out in the forest.

How it works

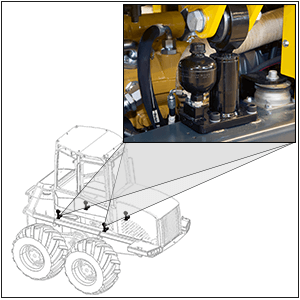

The CushionDrive™ system consists of four hydraulic cylinders, one under each corner of the cabin. Each cylinder has its own accumulator, which guarantees quick and smooth shock absorption. An extra hydraulic block is mounted under the cabin, without however reducing the accessibility to the rest of the components.

Flexible and operator friendly

The operator can easily adjust the system from the cabin to make it softer or harder. The CushionDrive™ can be deactivated at any time.