At Swedish Forestry Expo in the beginning of June, Eco Log´s new G series was launched and with the new machines an entirely new harvester cabin. The development behind the cabin is one of Eco Log´s longest projects so far and the road has been lined with quite a few challenges. Also, it has been a learning process to many parts of the company. The new harvesters in the G series are now waiting for production to start in

2024.

Behind the decision to develop a new harvester cabin are several factors. Future regulations, new design possibilities and, not the least, the demands and requests from the customers was finally decisive and a first pilot study was started in summer 2017.

– A new cabin has been requested from our customers for a long time and, initially, production start was set during the winter 2020/2021. So, already in 2017 the first pilot study was initiated as well as tests of a cabin suited for the harvesters in the E series, says Emil Forsblom, Head of Development at Eco Log.

What would happen next was something that no one could have predicted. Both the pandemic and the war in Ukraine caused major disturbances in the supply chain which made it impossible to keep the time schedule for the on-going cabin project.

– When a project gets delayed like this, it is more than just the time schedule that is affected. Several, large updates were going to be introduced on the harvesters at the same time as the new cabin and the G series – for example our new control system NexSci, new improved frames and updates in the hydraulic system. To phase different components in and out is complex and takes a lot of planning. So, when the cabin project was delayed several times, we couldn´t postpone the other updates any longer. Therefore, they were first implemented on the F series harvesters during 2022 and became what people call the F series – Phase 2, Emil explains.

To develop an entirely new cabin is, to say the least, an extensive task and the factors to consider are many. In a pilot study, all input from the market is gathered with a variety of different parameters, such as manufacturing costs, legal requirements, technical limitations, choice of suppliers and the conditions to manufacture and produce the product in an efficient way.

– Of course, the operator comes first regarding visibility, ergonomics, comfort and functionality. But there are a lot of things to consider and a huge job involving many people lies behind the development. Therefore, it feels great to be able to present this top-modern premium cabin that we are very proud of. It has really been a team effort from start to finish with many people involved who has performed an amazing job, says Emil.

When the development work really starts there are a variety of thorough tests and simulations that must be conducted to ensure that everything from climate, materials and electronics to visibility and, above all, safety is well functioning and meets various requirements and standards. Magnus Pettersson is one of everyone involved and he is also the one who has headed the project. Magnus tells us more about the development work and about different requests from the customers.

– A slightly different request is the turnable seat where the main reason was to create a space for having lunch without sitting with the food in your lap. This solution has then resulted in several advantages. As an example, there are plenty of space behind the seat to store your cooler bag or lunch bag and you can also spin the seat to get out of the cabin more easily. Another advantage is an easier service. Now, you can turn your seat around and easily access fuses, relays, diagnostic sockets and many other things that are placed under the panels behind the operator, says Magnus..

Storage possibilities is a recurring request from the customers and Eco Log´s development department has put a lot of effort to find smart storage solutions – a task that comes with a lot of challenges. The cabin must also accommodate large amounts of electronics, a ventilation system suited both for summer and winter, noise isolation and now, the turnable seat.

– There are a lot of things that must be fitted into the cabin and so, finding various storage options is definitely challenging and the engineers have really used every space available. Also, the operator needs an optimal visibility and the fact that we have the crane at the side of the cabin is another thing that affects that complexity. So yes, there has definitely been quite a lot of things to work out, but we are very pleased with the result, says Magnus.

Tests & Simulations

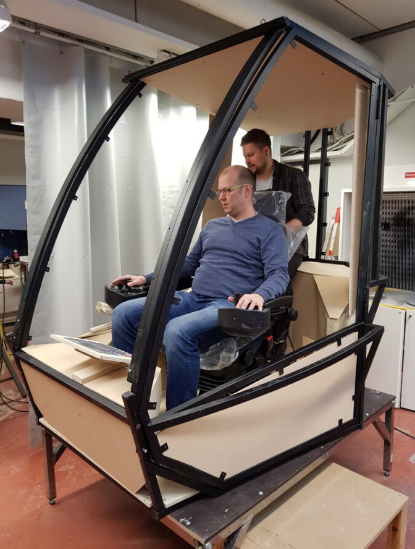

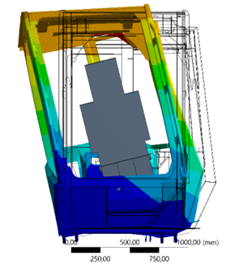

The tests and samples that needs to be conducted are many. To explain the extensive work, we describe a few of all of the tests that has been carried out during the project. Space studies and collisions can many times be performed trough 3D technique, but some of the tests needs a real model. The first one was made in wood interior to give a realistic feeling of the final result.

Safety tests

To Eco Log, driver safety is crucial. . We perform a lot of calculations on solidity and the possibilities to get out of the cabin in case of an accident. To verify all the calculations a couple of cabins are being tested. We simulate that a machine turns over (ROPS), release steel balls on the cabin to simulate a falling tree (FOPS) and ensures that the front windshield is resistant to chain shots. Also, OPS tests are carried out to make sure that the operator can´t be injured by example logs or other objects.

Climate tests

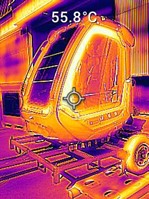

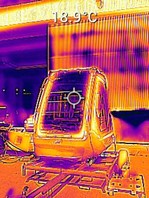

Test of the cooling system. The sun protection at the door measures a temperature of 55,8 °C, while the temperature through the front window is as low as 18,9°C.

The cabin has a new HVAC system. The preparations of the climate tests are made in a simulation program, both regarding air flow and capacity for heating and cooling. The optimized result could then be 3D printed and tested in the first prototype cabin. Repeated tests have then been carried out to ensure a system that fulfills our highest standards. There are also requirements deciding how a cabin should be cooled without causing air drafts around your neck. This also applies to heating and the possibility to have windows free from condensation.

To have as even airflow as possible doesn’t only provide a good defrosting, but it is also vital to the comfort for the operator. The requirements today states that it can only differ a maximum of five degrees between head and foot for the operator. Our measurements have shown a result of three-four degrees regarding heat as well as cold.

The cabin climate also includes floor heating, a newly developed system that has been thoroughly tested for an optimal temperature. Electric heating coils under the rubber mat makes snow and water dry quickly and gives a comfortable temperature to your feet or to your dog accompanying you in the machine. The challenge with floor heating is to create a system that provides a heated area that is as large as possible and in the same time safe to walk on and install without risk of causing damages to the system when handling the chair.

Testing various materials

The choice of different materials has also been tested, amongst others to see how the sun´s rays affect. Tests were performed in an UV chamber for more than 1000 hours, which according to standard is equal to approximately ten years of exposure of the sun. Periodically, samples were brought out from the chamber to be compared to original materials. Both wear- and scratch tests were performed on the surface to see if the material had become more sensitive. The UV-affected material was also brushed with hydraulic oil to see if that could have an impact on the lifespan of the material. Through these tests, some materials could be excluded, and others selected for use in a forest machine.

Many tests have also been carried out on the key-less system, both regarding the placement of antennas in the cabin, but also regarding functionality and reliability. The sensor for locking and unlocking has been tested to ensure that it works even if you are wearing gloves, if it rains or is cold outside. The key has been tested regarding reach, but has also been put down in mud to ensure that you can drop it in your tracks and still get in to the cabin.